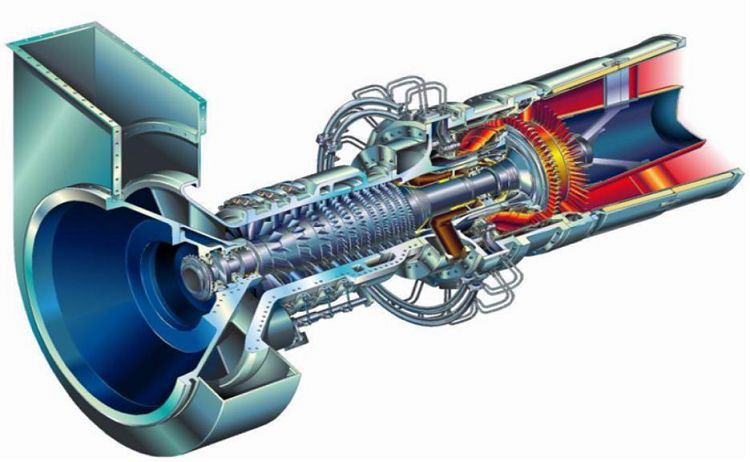

Micro gas turbine is a thermal generator characterized in less than one megawatt power, and rotor speed between tens to hundreds of thousands rpm.

Micro gas turbine generator set

Micro gas turbine is a thermal generator characterized in less than one megawatt power, and rotor speed between tens to hundreds of thousands rpm. Due to the compact structure and advanced technology application of high speed motor and air bearing, micro gas turbine has significant advantages on lifetime, mobility, reliability, fuel flexibility, noise, extensibility, emission, maintenance etc. Therefore, it has gradually become the core power equipment of natural gas distributing energy system, and it is widely used in small to medium-sized enterprises, office buildings, shopping malls, hospitals, hotels and other CHP or CCHP application scenarios.

E series of micro gas turbines, independently designed and manufactured by us, has filled the industrialization gap of China. Compared with foreign gas turbines, our micro gas turbine have some unique advantages. On the one hand, E series are value for money with the price per kilowatt only about 1/2 of those of foreign products. On the other hand, E series are uniquely adjustable in heat-electricity ratio with exhaust gas temperature available from 270℃ to 650℃, which significantly expands the application scenarios. In addition, E series have good fuel flexibility. They can not only use gas fuels including biogas, marsh gas, but also liquid fuels like diesel and methanol. Therefore, we can quickly customized the development on the demand of customers. Besides, our independently designed products are far superior to foreign as turbines regarding supply cycle, after-sales service, operation and maintenance service, which are more suitable for domestic markets.

No. | Item | Parameters | |||

1 | Model | E100 | E100-R1-N | E300 | |

2 | Rated electricity power | 135KWe | 110KWe | 390KWe | |

3 | Rated generating efficiency | 15% | 26% | 17% | |

4 | Rated exhaust gas temperature | 650℃ | 270℃ | 630℃ | |

QD50 gas turbine generator set

QD50 gas turbine generator sets, heavy-duty, is designed and packaged with GENP together, using GENP’S GE5-1 core engine, in accordance with GE’ standards and relevant China’s standards.

QD50 Performance(ISO condition,natural gas)

Power(MW) | 5.5 |

Electric efficiency(%) | 30.7 |

Heat Rate(kJ/kWh) | 11740 |

Pressure ratio | 14.8 |

Output shaft speed(rpm) | 16630 |

Exhaust temperature(℃) | 574 |

Exhaust Flow(kg/s) | 19.6 |

Emission(Nox /Co at 100% load)ppmv | 25/20 |

Characteristics

· Modular design, Low site assembly and maintenance time

·Automatic control systems, remote monitoring and diagnostics

·Avilable for site repairing/overhaul, Low maintenance costs

·Longer repairing/ maintenance interval, 12000 hours for combustion inspection(borescope),24,000 hours for HGPI,48000 hours for overhaul

·Low emission (25ppm)

Fuel

Natural Gas, Dual fuel, diesel, LNG, Biomass Gas etc

QD100 gas turbine generator set

QD100 gas turbine generator sets, heavy-duty, is designed and packaged with GENP together, using GENP’S GE10-1 core engine, in accordance with GE’ standards and relevant China’s standards

QD100 Performance(ISO condition,natural gas)

Power(MW) | 11.41 |

Electric efficiency(%) | 32.0 |

Heat Rate(KJ/KWh) | 11252 |

Pressure ratio | 15.6 |

Output shaft speed(rmp) | 11000 |

Exhaust temperature(℃) | 482.3 |

Exhaust Flow(kg/s) | 47.5 |

Characteristics

· Modular design, Low site assembly and maintenance time

·Automatic control systems, remote monitoring and diagnostics

·Avilable for site repairing/overhaul, Low maintenance costs

·Longer repairing/ maintenance interval, 8000 hours for combustion inspection(borescope),16,000 hours for HGPI,32000 hours for overhaul

Fuel

Natural Gas, Dual fuel, diesel, LNG, Biomass Gas etc.

QD160 gas turbine generator set

QD160 gas turbine generator sets, heavy-duty, is designed and packaged with GENP together, using GENP’S LT16 core engine, in accordance with GE’ standards and relevant China’s standards

QD160 Performance(ISO condition,natural gas)

Power(MW) | 16.1 |

Electric efficiency(%) | 36 |

Heat Rate(Kj/kWh) | 9999 |

Pressure ratio | 19 |

Speed(rpm) | 7800 |

Exhaust temperature(℃) | 490 |

Exhaust Flow(kg/s) | 54 |

Emission(Nox /Co at 100% load)ppmv | 25/15 |

Characteristics

· Higher availavility(98.6%)

·Modular design, Low site assembly and maintenance time

·Automatic control systems, remote monitoring and diagnostics

·Avilable for site repairing/overhaul, Low maintenance costs

·Longer repairing/ maintenance interval, 35000 hours for overhaul

·Low emission

Fuel

Natural Gas, Dual fuel, diesel, LNG, Biomass Gas etc.

DGG35gas turbine generator set

DGG35 gas turbine generator sets, heavy-duty, is designed and packaged with GENP together, using GENP’S MS5002E core engine, in accordance with GE’ standards and relevant China’s standards.

DGG35 Performance(ISO condition,natural gas)

Power(MW) | 32.757 |

Electric efficiency(%) | 35.85 |

Heat Rate(KJ/kwh) | 10041 |

Pressure Ratio | 17 |

Speed(rpm) | 5714 |

Exhaust temperature(℃) | 517.9 |

Exhaust Flow(kg/s) | 102.5 |

Emission(Nox /Co at 100% load)ppmv | 25/15 |

Characteristics

·Modular design, Low site assembly and maintenance time

·Automatic control systems, remote monitoring and diagnostics

·Avilable for site repairing/overhaul, Low maintenance costs

·Longer repairing/ maintenance interval, 48000 hours for overhaul

·Low emission

Fuel

Natural Gas, Dual fuel, diesel, LNG, Biomass Gas et

QD500 gas turbine generator set(SGT-800)

QD500 gas turbine generator sets, heavy-duty, is designed and packaged with GENP together, using Siemens’ SGT800 core engine, in accordance with GE’ standards and relevant China’s standards.

QD500 Performance(ISO condition,natural gas)

Power(MW) | 50.5 |

Electric efficiency(%) | 38.3 |

Heat Rate(KJ/kWh) | 9399 |

Pressure Ratio | 21.1 |

Output shaft speed(rpm) | 6600 |

Exhaust temperature | 553 |

Exhaust Flow(kg/s) | 134.2 |

Emission(Nox /Co at 100% load)ppmv | 15/5 |

Characteristics

·High electric efficiency 38.3%

·Modular design, Low site assembly and maintenance time

·Automatic control systems, remote monitoring and diagnostics

·Avilable for site repairing/overhaul, Low maintenance costs

·Longer repairing/ maintenance interval, 10000 hours for combustion inspection(borescope), 30,000 hours for HGPI,60, 000 hours for overhaul

·Low emission 15ppmv

Fuel

Natural Gas, Dual fuel, diesel, LNG, Biomass Gas etc.

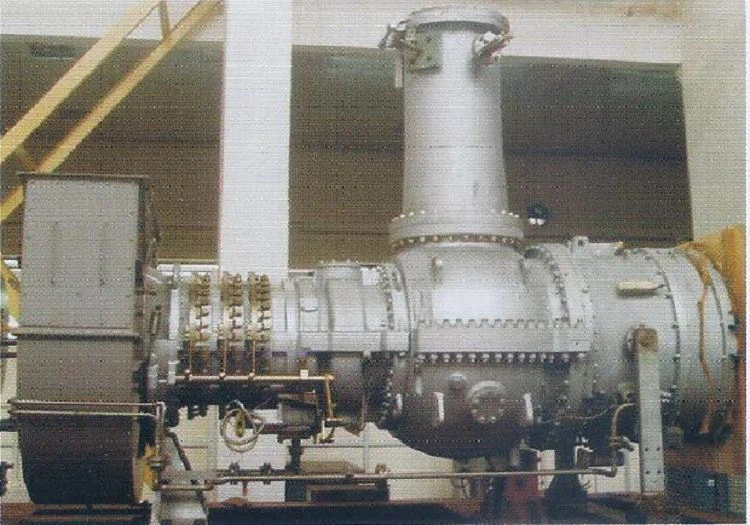

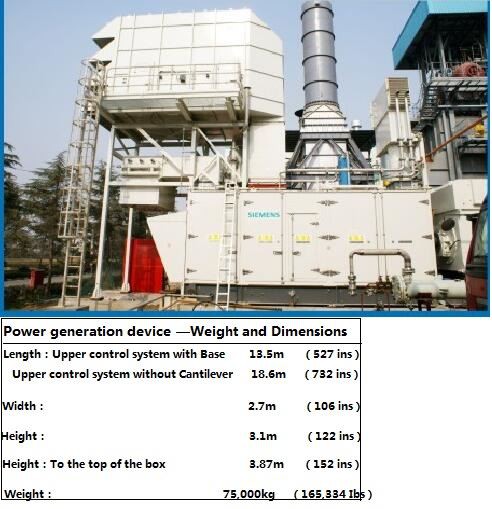

QDR20 heat-electricity co-generation package set

QDR20 heat-electricity co-generation package set is the high technology and main product of the company. It is recommended and promoted by the State for its advantages of energy saving, environmental protection and resource comprehensive utilization. It is suitable for developing and utilizing of inflammable industrial wasted gases such as coke oven gas, coal bed gas, waste gas of oil field and chemical exhaust gas etc, which are exhausted by metallurgical, petrochemical, coke, and coal field industries. Till now accumulated 40 sets have been delivered to the users and brought the users with mature, stable, reliable and energy saving product.

QDR20 Technical data

Output power(KW) | 2000 |

The most power (KW) | 2330 |

Steam output | ≥5.5-7.5t/h(0.8 ~1.3Mpa,160 ~300℃) |

Heat consumption | 15.65MJ/KWh |

Output voltage | 6.3 or 10.5KV |

Frequency | 50 Hz |

Total heat efficiency | ≥75% |

Cooling water consumption | ≤ 3t/h |

Soft-water(for boiler) | 8t/h |

Characteristics

·Invest losser, run cost losser

·Benefit better, invest reclaim time ≤ 3 years(contain construct time)

·Start-up rapider, from stop to run of all loads, the time<five minutes.

·Configuration in reason, area is small.

·Heat-electricity efficiency better: Comprehensive efficiency≥ 75%

·Automation extent higher, operation easier. Can automatism carry out start-up, excitation, combine net, power adjust, protect function, and automatism track record parameter of unit run in 3 minutes.

·Have generate electricity independently and combine net generate electricity capability.

·Fuel hot confine:2300kCal/Nm³ ~11000 kCal/Nm³.

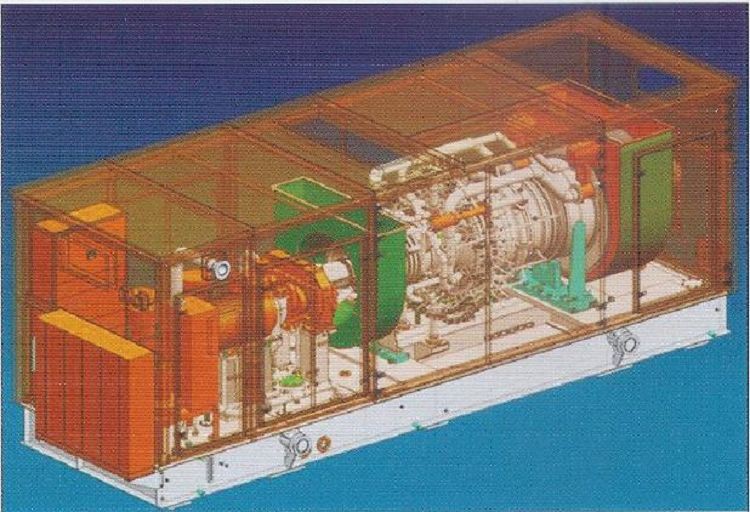

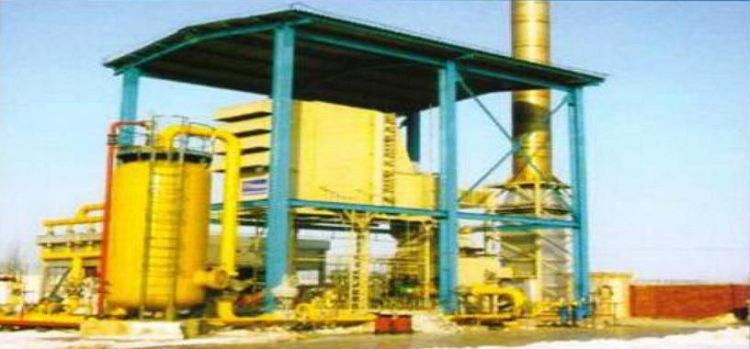

QDRA70 heat-electricity co-generation package set

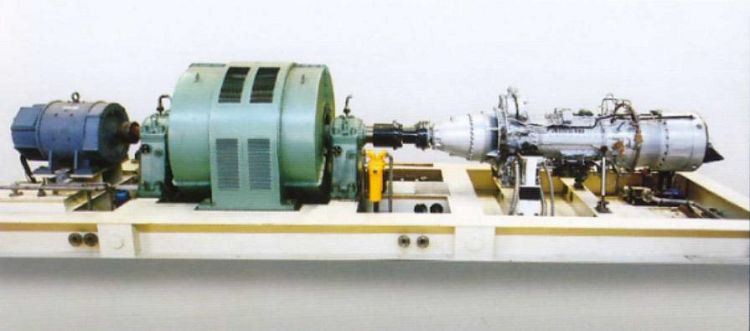

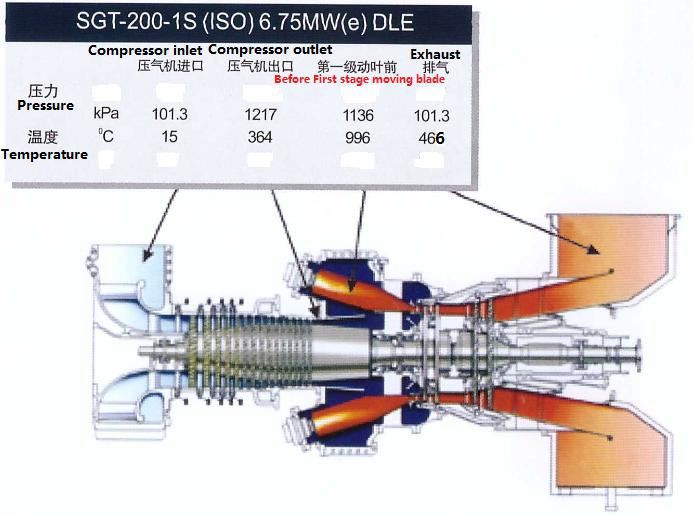

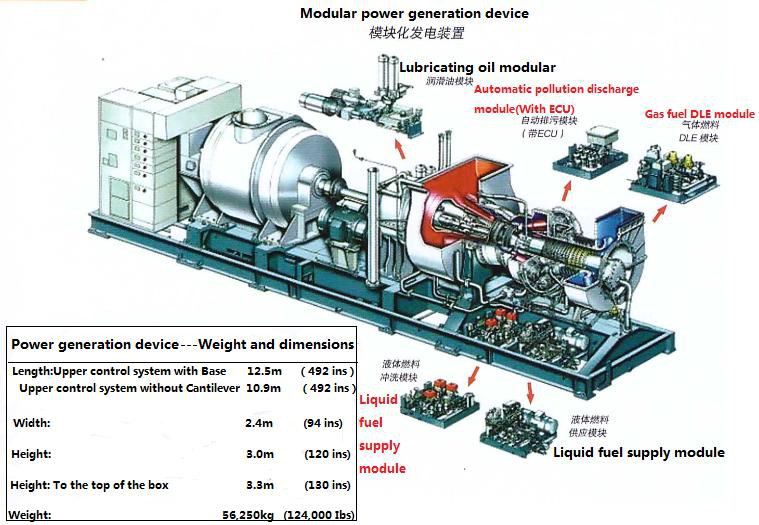

QDRA70 gas turbine generating set which adopts Siemens’ SGT200 gas turbine possesses the characteristics of simple design, reliable operation, less emission, and excellent performs. It is able to burn liquid fuel and gas fuel of different kinds. The modular integrated design concept is adopted in the generating set. The modules are assembled as an integrated unit and installed on a standard base after the pre-assembly and the factory testing, which is very convenient for transportation, installation and field maintenance. During industrial power generating, the heat in the high temperature exhaust from the gas turbine can be reused by the heat recovery boiler, which makes the whole comprehensive heat efficiency up to 85%.

QDRA70 Technical data

Type | QDRA70 |

Power | 6.75MW |

Electrical efficiency | 31.5% |

Heat consumption | 11.418MJ/KWh |

Turbine speed | 11053rpm/min |

Pressure ratio | 12.2:1 |

Exhaust flow, temperature | 29.3kg/s, 469℃ |

Output voltage | 10.5or 6.3kv |

Steam output | 11-14t/h |

Fuel | Natural Gas, Coke oven gas, biogas |

Nox emissions(with DLE, corrected to 15% O2 dry) | ≤ 25ppmV |

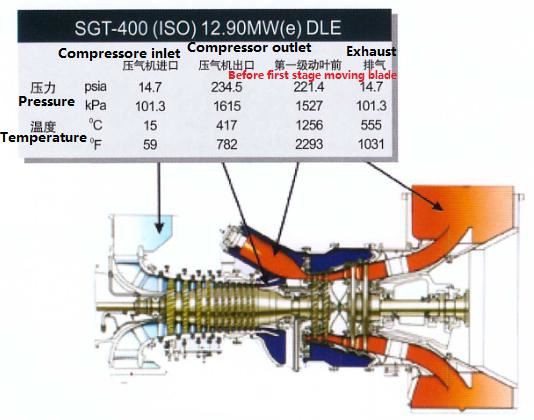

QDR129 heat-electricity co-generation package set

The core engine of QDR129 generator unit is specially designed for application of electrical power generating purpose, which has two stage power turbines and adopts the updated aerodynamics and combustion technology in the design. It enjoys the compact arrangement, good field serviceability, high reliability, short investment return period, stable and economical power output and strong steam supply capacity. It becomes the first choice of the gas turbine for petroleum and natural gas industry application.

QDR129 Technical data

Power Generation | 12.90MW |

Fuel | Natural gas |

Frequency | 50/60Hz |

Electrical efficiency | 34.8% |

Heat rate | 10.355MJ/KWh |

Turbine speed | 9500rpm |

Compressor pressure ratio | 16.8:1 |

Exhaust gas flow/temperature | 39.4kg/s, 555℃ |

Nox emissions(with DLE, corrected to 15% O2 dry) | <25ppmV |

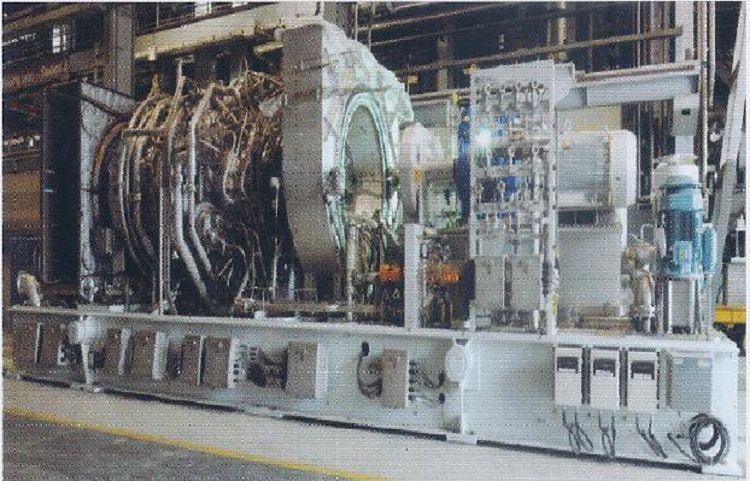

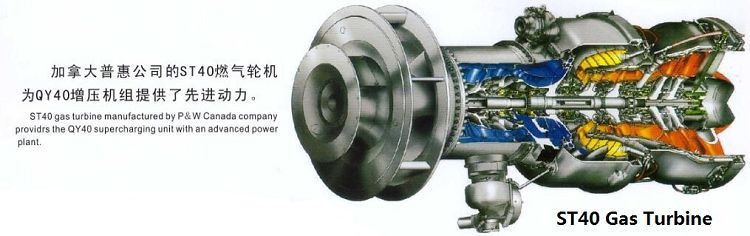

QY40 supercharging unit

QY40 supercharging unit adopts ST40 gas turbine of P&W Canada company as its power plant and PCL 303 centrifugal compressor technology imported from Italy. The whole set of gas turbine package is controlled by the computer and has world advanced level. It is the best choice for supercharging the natural gas in long distance transportation for the project of “West-east nature gas transmission” in China.

QY40 supercharging unit apply to those booster stations which use the natural gas long transport pipes of loss pressure ratio(1.2-1.55),big flow(7 hundred million-14 hundred million).We could also retrofit the compressor with which we can boost for other gas and liquid as per the customers’ request.

QY40 Supercharging unit technical data

Rating transport gas flux | 12 hundred million Nm3/a |

Gas inlet pressure | 3.7 ~4.5MPa |

Gas outlet pressure | 6.5MPa |

Gas inlet temperature | >40℃ |

Gas outlet temperature | >78℃ |

Run rotate speed | 11500~15000r/min |

Unit life | 30 years |

Power | 4039KW |

Heat efficiency | 33.1% |

Exhaust flow | 13.9kg/s |

Exhaust temperature | 544℃ |

Speed of high pressure rotor | 29549r/min |

Speed of power turbine | 14875r/min |

Net weight | 525kg |

General pressure ratio | 17.05 |

Truck-carried Gas Turbine Generating Set

Beijing Jinrun Taihe gas turbine series truck-carried gas turbine generating set adopts advanced gas turbine developed by Beijing Jinrun Taihe independently, control and protection technology, integrated technology and mute technology. It features reliable function, simple operation, easy maintenance, high power of the electricity produced etc, and is used widely on many fields of urban emergency power supply, rescuing operation, emergency power supply and military equipment etc. Generally it is composed of power generating truck and auxiliary truck.

A.Power Generating Truck

The power generating truck adopts advanced air-in and out muffler devices and housing, in order to effectively control the noise around generating set. Good ventilating device ensuring the temperature of generator room as operating could meet requirement on working environment temperature for all components and devices. The auxiliary equipment and electric control system of generating set are all installed in generator room, which actualizes high-integration of generating set. There is the operation display panel in the control booth which is at the rear side of room, and the hand-held computer and operation handle in automobile cab. The hand-held computer could actualize the remote monitor to generating set and operated handle could actualize the remote operation to generating set.

B.Auxiliary Truck

The auxiliary truck provides cable used for power generating and fuel used for 6 hours operation of truck-carried generating. It features cross-country operation, high adaptability and field works, etc, as well as used as fuel transport vehicles independently.

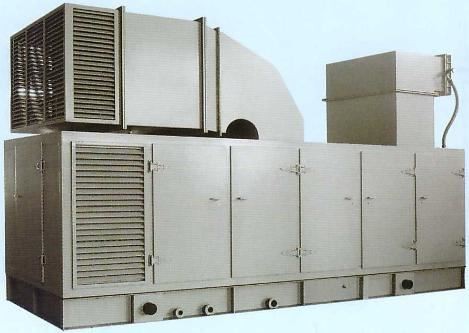

Stationary Gas Turbine Generating Set

Beijing Jinrun Taihe series stationary gas turbine generating set, which is a high-tech product with features of quick-response, reliability, automation, unmanned operation, safety and environment protection, can provide customers with continuously-running generating set and emergency power. The power plant of stationary gas turbine generating set is the gas turbine developed and manufactured on the basis of aviation engine technology. It features high automation, reliable start, stable voltage and frequency, harmonic-wave interference prevention, high resistance capability to loading mutability, small size and light weight, low noise, cooling water not needed, easy operation and maintenance etc. Fuels as diesel, kerosene, natural gas, coal gas and industry waste gas etc. can be used at the choice of the users.

The stationary gas turbine generating set with power of 1200~3000KW fills many domestic gaps in the fields of emergency gas turbine generating set and is in Guangzhou, Shantou, Shanghai, Beijing, Zhengzhou, Changchun, Hangzhou, etc.

A.QD12、QD14、QD16 Stationary Gas Turbine Generating Set(1200kw-1600kw)

Stationary gas turbine generating set of QD12、QD14、QD16 type mainly consists of gas turbine, electric generator, shaft coupling, fuel system, oil system, intake system, exhaust system, electric control system, control protection system, sound insulation housing, base and engine room ventilation system, etc.

Stationary gas turbine generating set of QD16 type developed and manufactured in 1998, which passed the product qualification organized by Information Industry Ministry And Aviation Industry Corporation, is the first gas turbine generating set in China used for tel-communication.

B.QD30C Gas Turbine Generating Set(3000kw)

QD30C stationary gas turbine generating set is the maximum power communication genset within China. It satisfies the increasing requirements of high level emergency power supply in communication fields in China.

QD30C stationary gas turbine generating set is the first domestic genset with double gas resistance capability to over loading, and is in the leading place domestically and ranks a high level internationally in the field of double gas turbine technology application.

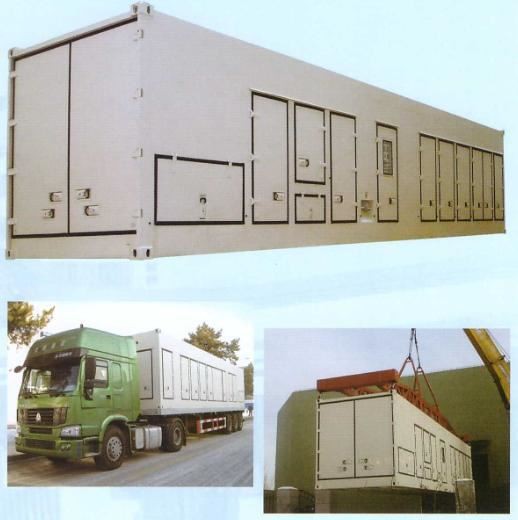

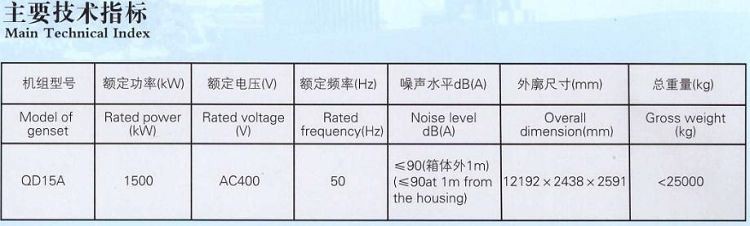

Container Type Gas Turbine Generating Set

QD15A Container type gas turbine generating set, with external structure designed according to standard 1AA container, has the futures including high quality of electricity generating, great output power, high successful starting rate, rapid loading, and good reliability, etc. It integrates the advantages of both stationary generating set and truck-carried one, being easy for transportation, with such high adaptability, and capable to operate independently in the air without the specific machine room. Besides the application as general standby power supply, such generating set can also be used as power supply for emergency and disaster relief as well as military battlefield.

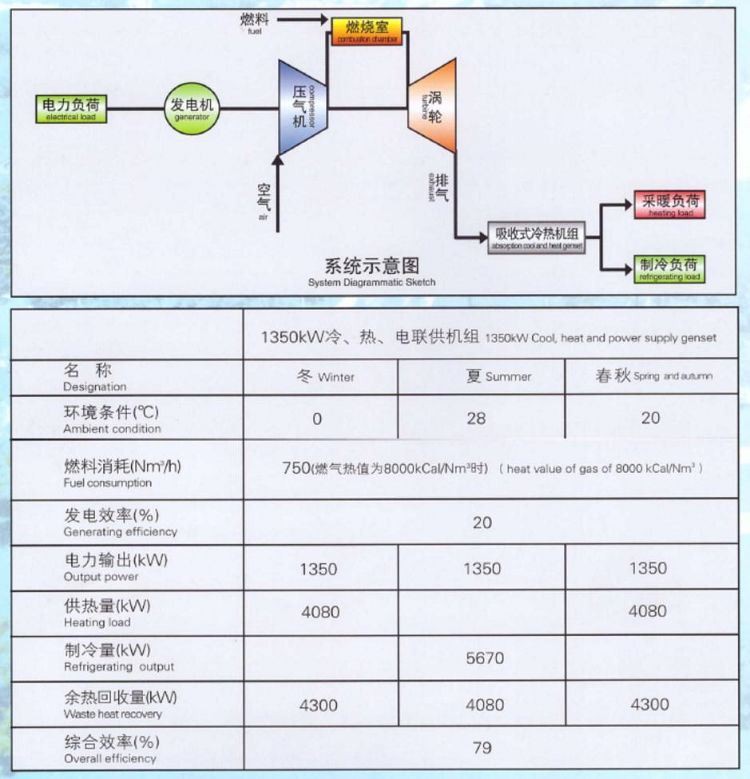

Gas Turbine Cool, Heat and Power Supply Genset

The gas turbine power generating set can also be used to constitute the heat and power supply genset or cool, heat and power supply genset with exhaust-heat boiler or lithium bromide generating set. Comparing with the simple power supply system, the cool, heat and power supply system can increase the system energy utilization largely, decrease environmental pollution due to widespread applicability of fuel. Therefore, the cool, heat and power supply system have extensive applicable future on distributed power supply field.

Hot Tags: gas turbine and compressor, China, manufacturers, suppliers, factory, customized, buy, cheap, Gas Turbine Air Intake System, Components Refurbishment, Generator For Gas Turbine Power Plant, Gas Turbine And Compressor